Cranes and hoists selection of wire ropes drums and sheaves 1 scope this international standard specifies the minimum practical design factors zp for the various classifications of mechanism rope types rope duties and types of spooling and demonstrates how these are used in the determination of the minimum breaking force of the wire rope.

Wire rope drum design manual.

When each drum has its own independent drive the terms dual winch or triple winch are appropriate.

Navy wire rope handbook voliue i accesion to f oil pals cra z v ic tab design and engineering of wire rope systes w wnannounce published by direction of commander naval sea systems command.

Wire rope drum is a part of crane lifting mechanism which is used to full in entwine and store wire rope.

Roland verreet the steel wire rope of a properly designed and maintained crane should have a reasonably long service life and one day be discarded because of fatigue the wire rope equivalent of old age.

Dongqi drum design and drum production.

Wire rope wire rope diameter shall be decided by maximum rope tension which is calculated by using pulley eiiiciency.

Grooved drums as in this case the rope is already guided by the grooves themselves.

But often wire ropes don t get very old.

The wire rope shall bemade irom improved plough steel galvanized ii required lang s lay and iibre core or normally oi 6 x 36 or 6 x 37 construction and shall coniorm to 1s 2266.

Completely the implications of correct rope design manufacturing use and inspection as the real mandatory requirement must be.

3 design manual for winch systems design basis nomenclature design basis lifting load m h t lifting speed v h m min lifting height h m number of fixed deflection sheaves between drum and hoist or moving part n u required service life t h number of winding layers on a drum n l number of parallel hoists or ropes reeved on a drum n.

This paper addresses the design of a rope drum for manual winch application and.

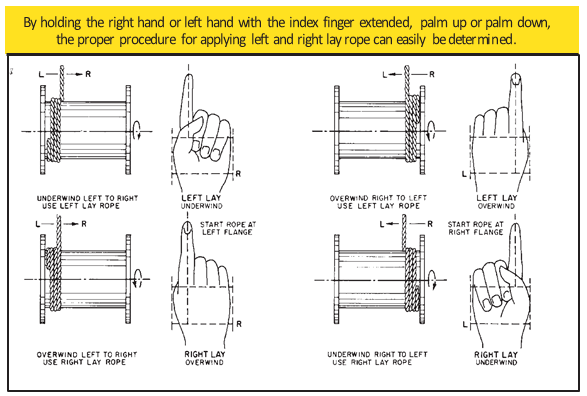

Information about design of sheave and drum diameter the shape of the groove profiles and corresponding radius the drum pitch and the fleet angle is given in this article.

The wire rope drum is consisted of drum shaft flange type annular gear drum hub bearings bearing pedestal etc.

In case of grooved.

That prevent the wire rope from twistin g and re sult in pinchin g and damaging of the rope.

Performance of wire rope in a machine is affected by design of its sheaves and drums.

New wire rope designs for multi layer drums by dipl ing.