Laminated glass is now being used for safety security structural and decorative components of buildings.

Will cutting a laminated paper cause it to delaminate.

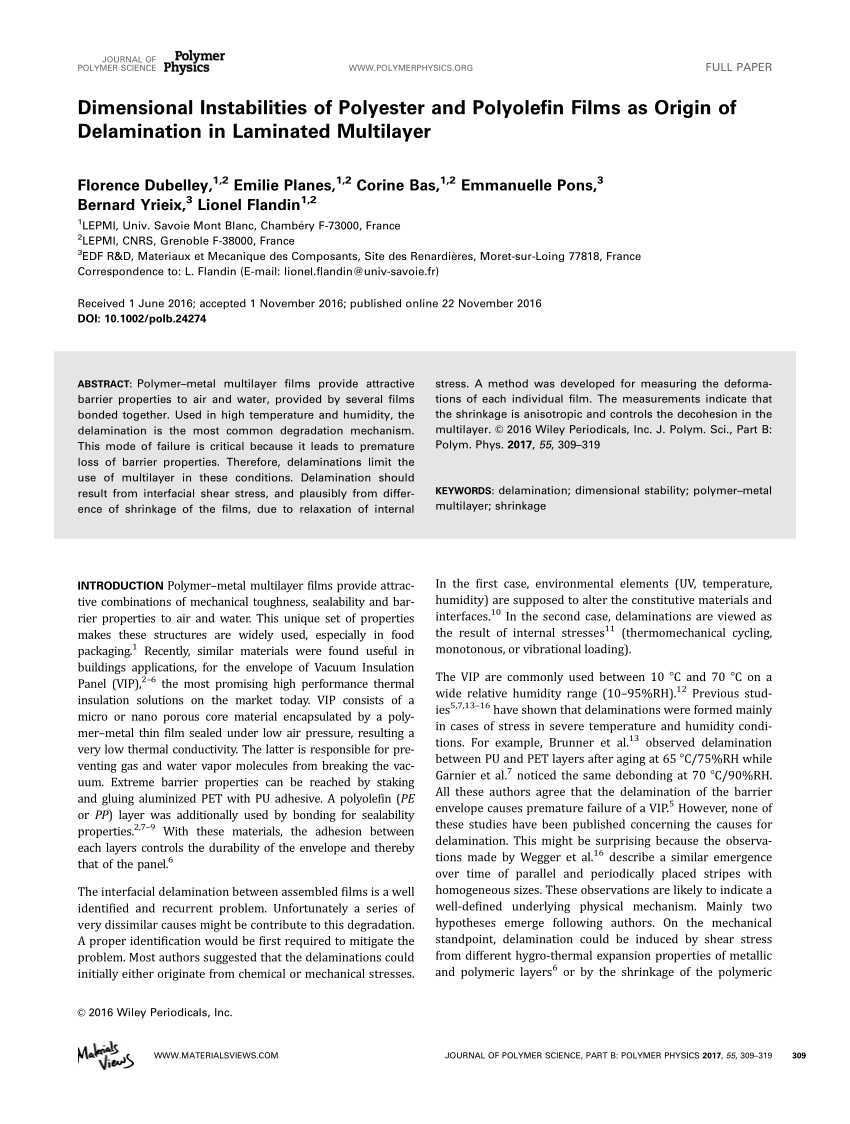

Also surface coatings such as paints and films can delaminate from the coated substrate.

Shaw and tseng 59 described the phenomenon of delamination in terms of linear fracture mechanics.

Some people choose to cut paper items and then laminate them.

Laminating is a useful process that helps preserve paper by waterproofing it and preventing mold bacteria rust or other contaminants.

Laminated glass does not do well in the presence of water which can cause it to delaminate.

In time the separations swell as the delaminations get worse and migrate into the interior of the plywood.

The most common cause of this type of localized delamination is the use of clamping devices on the edges of laminated tempered glass during the autoclaving of the laminated glass.

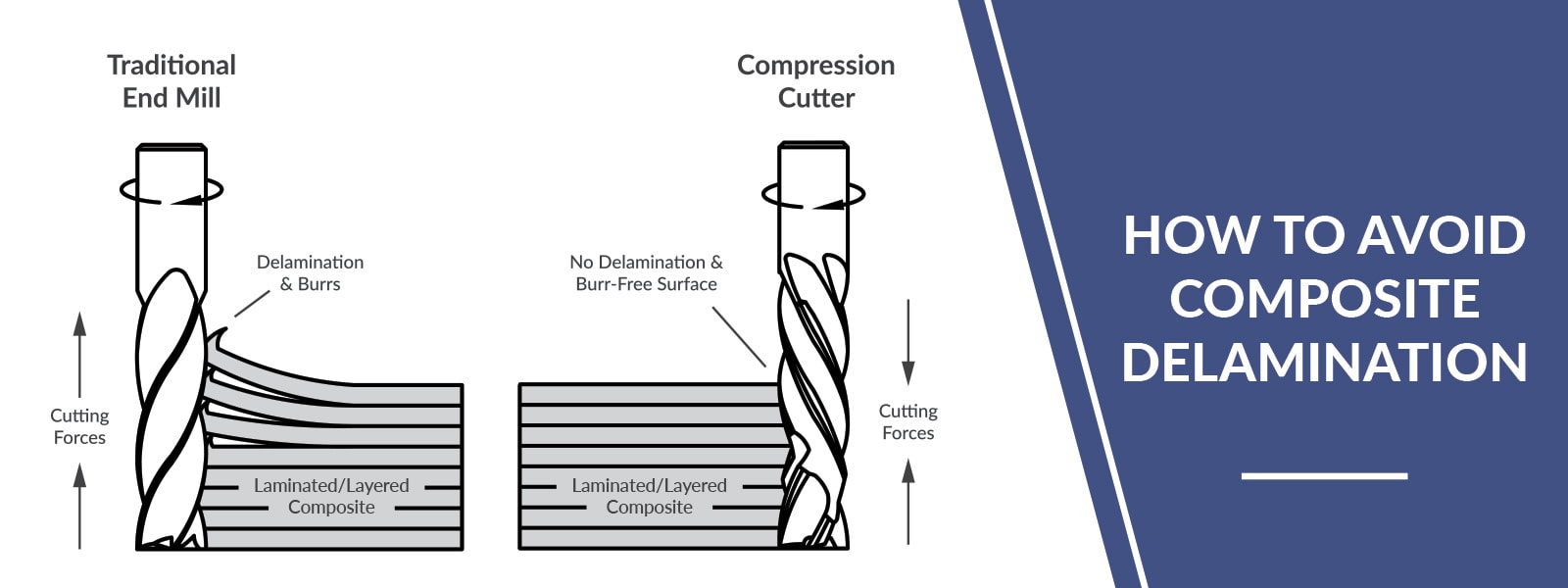

Delamination is also noticed in awj cutting of composites at low abrasive flow rate and high traverse speeds 54 57.

This can be time consuming.

If the issue is very severe the laminate boards can become chipped or even fracture apart at delaminated areas.

Lamination has proven to be destructive to paper and ultimately destroys the protected document.

This is good if your documents are not to be preserved for an extended period of time or forever.

My rollers have residual adhesive stuck to them.

It was considered that the last supported layers in the structure function as an elastic plate that could deform elastically under the jet pressure.

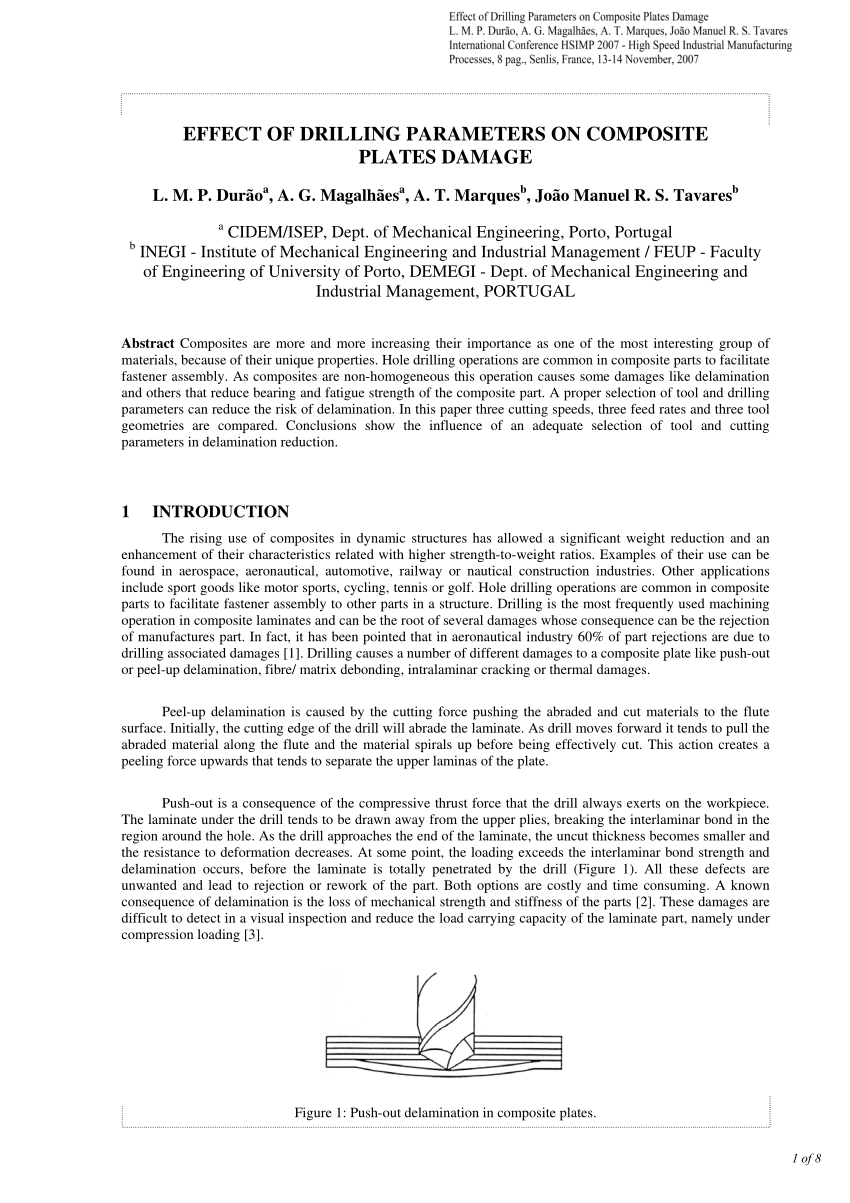

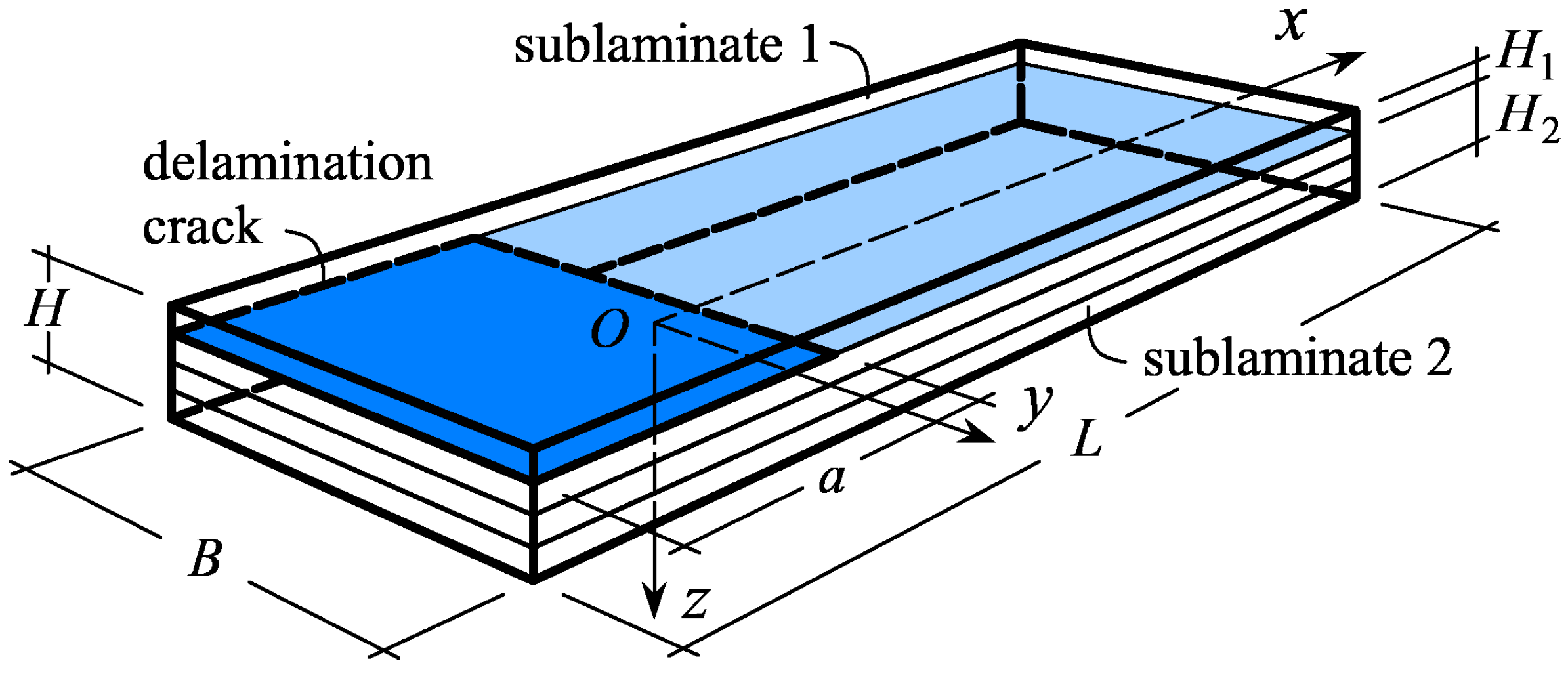

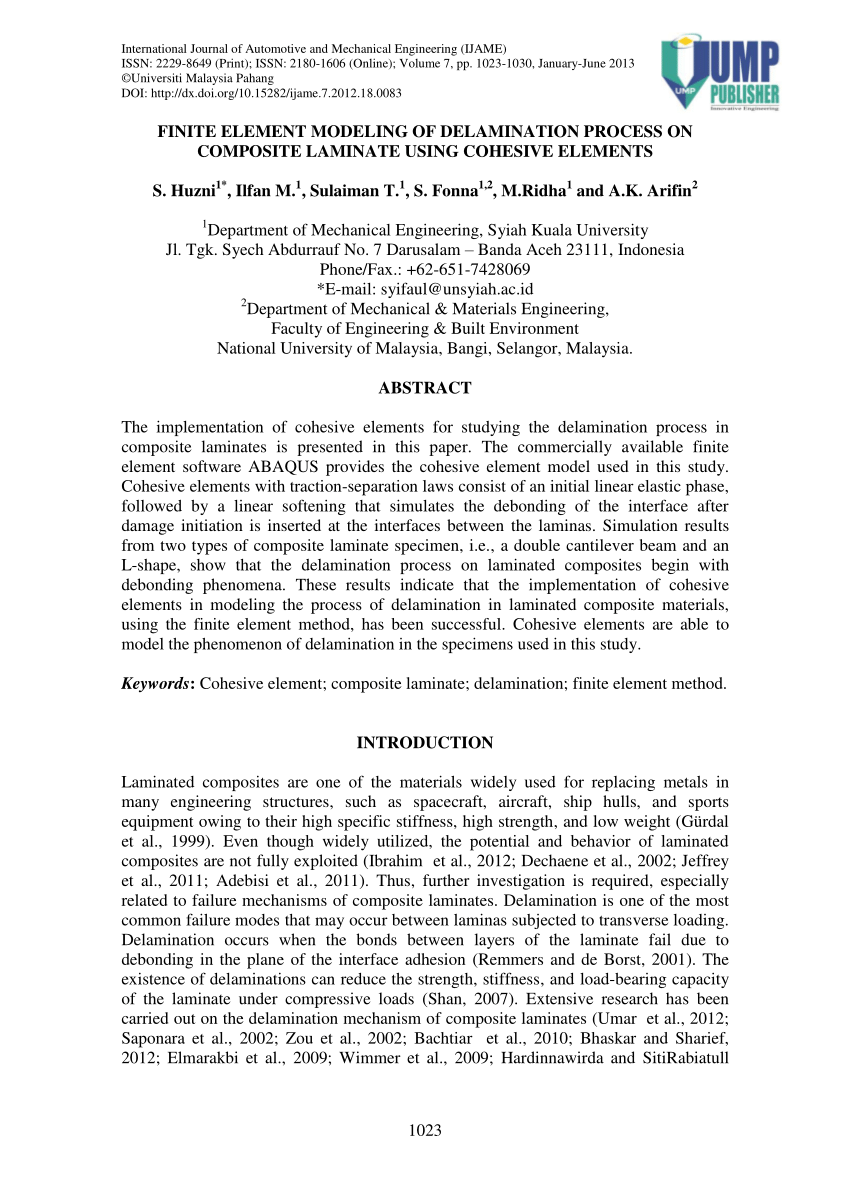

Delamination is a mode of failure where a material fractures into layers.

When this occurs the paper absorbs the moisture and causes the lamination adhesive to release or delaminate.

In laminated composites the adhesion between layers often fails first causing the layers t.

Removing lamination from paper is a delicate process involving either heat or chemicals and must be performed with care if the document is to be saved.

Delamination normally takes place when laminated composites are cut with high velocity water jets 54 55 57 58.

Trimming away more than that may result in some or all of the edges becoming exposed to moisture or humidity.

This paper will focus on the edge stability of pvb and ionoplast laminates and address the potential causes of blemishes.

A variety of materials including laminate composites and concrete can fail by delamination.

It usually requires a frame to protect it from delamination although some manufacturers have developed laminated glass with exposed edges.

The role of glass in building construction has drastically changed in recent years.

The pressure from a nail or screw bends the ends or sides of the thin layers up or down separating them just enough for moisture to penetrate between them.

Delaminated laminate floor board.

Processing can create layers in materials such as steel formed by rolling and plastics and metals from 3d printing which can fail from layer separation.